Direct liquid cooling data center refers to a number of different cooling approaches that all share the same characteristic of transferring waste heat

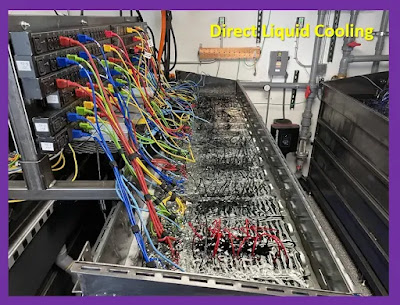

Direct liquid cooling data center refers to a number of different cooling approaches that all share the same characteristic of transferring waste heat to a fluid at or very near the point it is generated, rather than transferring it to room air and then conditioning the room air. There are several approaches to implementing liquid cooling for data center equipment. One option, currently available as an option from many rack manufacturers, installs cooling coils directly onto the rack to capture and remove waste heat. The underfloor is often used to run the coolant lines that connect to the rack coil via flexible hoses. Many other approaches are available or being pursued, ranging from water cooling of component heat sinks to bathing components with dielectric fluid cooled via a heat exchanger.

Direct Liquid cooling data center can serve higher heat densities and be much more efficient than traditional air cooling. A high efficiency approach to cooling data center equipment takes advantage of liquid cooling’s ability to efficiently move heat by transferring the waste heat from racks to a liquid loop as close to the heat source as possible, at the highest possible temperature. Currently, the most common approach is to use a chilled water coil integrated in some manner into the rack itself. Liquid cooling is adopted for reasons beyond efficiency; it can also serve higher power densities (W/sf). Energy efficiencies will be realized when such systems allow the use of a medium temperature chilled water loop (55-60°F rather than 44°F) and by reducing the size and power consumption of fans serving the data center. In the future, products may become available that allow for direct liquid cooling of data center servers and equipment more directly, via methods ranging from fluid passages in chip heat sinks to submersion in a dielectric fluid. While not currently widely available, such approaches hold promise and should be evaluated as they continue to mature and are commercialized for the data center equipment market.

Principles Direct Liquid Cooling

A cooling system using water as the heat transport medium can conduct about 3,500 times more heat on a volume basis than a system using air. For example, one gallon of water per minute (not a particularly large water flow) will remove the thermal equivalent of a kilowatt with a seven-degree temperature rise. By comparison, removing a kilowatt with air requires passing 140 cubic feet (1,050 gallons) of air per minute through the rack at a 23-degree temperature rise. In addition, the low temperature rise of the water flow would allow for relatively warm water to be used for cooling; modern cooling equipment is more efficient when it is producing warmer temperatures, and use of free cooling or a water-side economizer could eliminate high-energy-use compressor cooling from the cooling system altogether. While liquid has a huge advantage in heat removal efficiency, and was a common approach in the dawn of the mainframe era, the use of liquids in data centers is a hotly debated issue. However, as chip power continues to rise and equipment loads continue to increase in density, liquid cooling becomes increasingly inevitable as a strategy for cooling the rapidly increasing equipment load density (measured in W/sf).

The first cost of the coil option and additional required piping should be compared to an analysis of expected energy, mechanical equipment, and/or architectural savings. The most significant energy savings are achieved when the liquid cooling system is paired with a water-side economizer or free cooling. Direct liquid cooling directly replaces air handler or computer room air conditioner (CRAC) capacity. A data center that fully utilizes direct liquid cooling can be served like a standard office space by the air-side system. Architectural savings are less common, but can be significant if the use of water cooled racks allows for a reduction in the square footage of the data center by allowing a higher equipment density. In small data centers serving existing buildings, water-cooling may allow a standard ‘office’ space to be used as a data center without the need for costly space retrofits. Beyond a traditional coil mounted on the rack to cool the exhaust airstream, other approaches under development tend to keep liquid well away from the chips by using various non-liquid-based methods to move heat from the electronics to the liquid in an off-board or even outside-the-rack location. Heat pipes, carbon fibers, and a few other non-liquid media can transfer heat to a backplane liquid system, eliminating the need to have the water near the chips. Separating the two helps relieve anxieties about mixing water, or any liquid, with electricity. Direct liquid cooling of components is not currently available in the general, non supercomputer, server market, but is also an approach that has a high potential for realizing significant energy saving opportunities and may be used in future commercial offerings. Direct liquid cooling through the use of chip heat sinks with liquid passages, while not common commercially at the moment, is a mature technology that can offer significant efficiency savings if available.

Direct Liquid cooling data center can serve higher heat densities and be much more efficient than traditional air cooling. A high efficiency approach to cooling data center equipment takes advantage of liquid cooling’s ability to efficiently move heat by transferring the waste heat from racks to a liquid loop as close to the heat source as possible, at the highest possible temperature. Currently, the most common approach is to use a chilled water coil integrated in some manner into the rack itself. Liquid cooling is adopted for reasons beyond efficiency; it can also serve higher power densities (W/sf). Energy efficiencies will be realized when such systems allow the use of a medium temperature chilled water loop (55-60°F rather than 44°F) and by reducing the size and power consumption of fans serving the data center. In the future, products may become available that allow for direct liquid cooling of data center servers and equipment more directly, via methods ranging from fluid passages in chip heat sinks to submersion in a dielectric fluid. While not currently widely available, such approaches hold promise and should be evaluated as they continue to mature and are commercialized for the data center equipment market.

Principles Direct Liquid Cooling

- Water flow is a very efficient method of transporting heat. On a volume basis, it carries approximately 3,500 times as much heat as air.

- Cooling racks of IT equipment reliably and economically is the main purpose of the data center cooling system; conditioning the data center room without the rack load is a minor task in both difficulty and importance.

- Capturing heat at a high temperature directly from the racks allows for much greater use of water-side economizer free cooling, which can reduce cooling plant energy use by 70%1 or more when operating.

- Transferring heat from a small volume of hot air directly off the equipment to a chilled water loop is more efficient than mixing hot air with a large volume of ambient air and removing heat from the entire mixed volume. A water-cooled rack is equivalent to an almost perfect hot aisle/cold aisle configuration, where recirculation of waste heat is eliminated and the ‘hot aisle’ heat exhaust can be run at very high temperatures with no impact on workers or equipment in the data center room.

- Direct liquid cooling of components offers the greatest cooling system efficiency by eliminating airflow needs entirely. When direct liquid component systems become available, they should be evaluated on a case by-case basis.

A cooling system using water as the heat transport medium can conduct about 3,500 times more heat on a volume basis than a system using air. For example, one gallon of water per minute (not a particularly large water flow) will remove the thermal equivalent of a kilowatt with a seven-degree temperature rise. By comparison, removing a kilowatt with air requires passing 140 cubic feet (1,050 gallons) of air per minute through the rack at a 23-degree temperature rise. In addition, the low temperature rise of the water flow would allow for relatively warm water to be used for cooling; modern cooling equipment is more efficient when it is producing warmer temperatures, and use of free cooling or a water-side economizer could eliminate high-energy-use compressor cooling from the cooling system altogether. While liquid has a huge advantage in heat removal efficiency, and was a common approach in the dawn of the mainframe era, the use of liquids in data centers is a hotly debated issue. However, as chip power continues to rise and equipment loads continue to increase in density, liquid cooling becomes increasingly inevitable as a strategy for cooling the rapidly increasing equipment load density (measured in W/sf).

The first cost of the coil option and additional required piping should be compared to an analysis of expected energy, mechanical equipment, and/or architectural savings. The most significant energy savings are achieved when the liquid cooling system is paired with a water-side economizer or free cooling. Direct liquid cooling directly replaces air handler or computer room air conditioner (CRAC) capacity. A data center that fully utilizes direct liquid cooling can be served like a standard office space by the air-side system. Architectural savings are less common, but can be significant if the use of water cooled racks allows for a reduction in the square footage of the data center by allowing a higher equipment density. In small data centers serving existing buildings, water-cooling may allow a standard ‘office’ space to be used as a data center without the need for costly space retrofits. Beyond a traditional coil mounted on the rack to cool the exhaust airstream, other approaches under development tend to keep liquid well away from the chips by using various non-liquid-based methods to move heat from the electronics to the liquid in an off-board or even outside-the-rack location. Heat pipes, carbon fibers, and a few other non-liquid media can transfer heat to a backplane liquid system, eliminating the need to have the water near the chips. Separating the two helps relieve anxieties about mixing water, or any liquid, with electricity. Direct liquid cooling of components is not currently available in the general, non supercomputer, server market, but is also an approach that has a high potential for realizing significant energy saving opportunities and may be used in future commercial offerings. Direct liquid cooling through the use of chip heat sinks with liquid passages, while not common commercially at the moment, is a mature technology that can offer significant efficiency savings if available.

- [accordion]

- (1) Direct-to-Chip Liquid Cooling for Data Centers

-

- (2) Understanding Data Center Liquid Cooling

- (3) Data Center Trends Use of Liquid Cooling

- (4) Data Center and IT Equipment Liquid Cooling

- (5) Liquid Cooling Rack Data Center

- (1) Direct-to-Chip Liquid Cooling for Data Centers

- (2) Understanding Data Center Liquid Cooling

- (3) Data Center Trends Use of Liquid Cooling

- (4) Data Center and IT Equipment Liquid Cooling

- (5) Liquid Cooling Rack Data Center

M. Rizka Anugrah

M. Rizka Anugrah Rani Annisa Royani

Rani Annisa Royani