Air management in data centers encompasses all the design and configuration aspects that go into limiting or eliminating mixing between cooling air su

Air management in Modern data center equipment racks can generate intense heat loads. Designing to achieve precise control of the air flow through the room that collects and removes equipment waste heat has a significant impact on energy efficiency and equipment reliability in facilities of all sizes, from a small data center supporting office buildings to dedicated co-location facilities. Air management in data centers encompasses all the design and configuration aspects that go into limiting or eliminating mixing between cooling air supplied to equipment and hot air rejected from the equipment. When properly constructed, an air management system can reduce operating costs, first-cost equipment investment, data center density (W/sf) capacity, and heat-related processing interruptions or failures. The position of supply and return, the configuration of equipment's air intake and heat exhaust ports, and the large-scale airflow patterns in the space are a few major design concerns.

Principles Air Management

Fan energy savings are realized by reducing fan speeds to only supply as much air as a given space requires. There are a number of different design strategies that reduce fan speeds, but the most common is a fan speed control loop controlling the cold aisles’ temperature at the most critical locations – the top of racks for underfloor supply systems, the bottom of racks for overhead systems, end of aisles, etc. Note that many computer room air conditioners use the return air temperature to indicate the space temperature, an approach that does not work in a hot aisle/cold aisle configuration where the return air is at a very different temperature than the cold aisle air being supplied to the equipment. Control of the fan speed based on the server inlet temperature is critical to achieving savings. Higher return air temperature also makes better use of the capacity of standard package units, which are designed to condition office loads. This means that a portion of their cooling capacity is configured to serve humidity (latent) loads. Data centers typically have very few occupants and small ventilation air requirements (assuming no air-side economizing in a typical facility), and therefore have negligible latent loads. While the best course of action is to select a unit designed for sensible-cooling loads only or to increase the airflow, an increased return air temperature can convert some of a standard package unit’s latent capacity into usable sensible capacity very economically. This may reduce the size and/or number of units required.

Air Management Hot Aisle/Cold Aisle

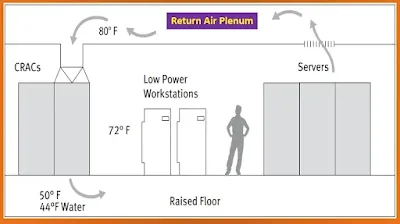

A basic hot aisle/cold aisle configuration is created when the equipment racks and the cooling system’s air supply and return are designed to prevent mixing of the hot rack exhaust air and the cool supply air drawn into the racks. As the name implies, the data center equipment is laid out in rows of racks with alternating cold (rack air intake side) and hot (rack air heat exhaust side) aisles between them. The aisles are typically wide enough to allow for maintenance access to the racks and meet any code requirements. All equipment is installed into the racks to achieve a front-to-back airflow pattern that draws conditioned air in from cold aisles, located in front of the equipment, and rejects heat out through the hot aisles behind the racks. Equipment with non-standard exhaust directions must be addressed in some way (shrouds, ducts, etc.) to achieve a front-to-back airflow. The rows of racks are placed back-to-back, and holes through the rack (vacant equipment slots) are blocked off on the intake side to create barriers that reduce recirculation. With proper isolation, the temperature of the hot aisle no longer impacts the temperature of the racks or the reliable operation of the data center; the hot aisle becomes a heat exhaust. The HVAC system is configured to supply cold air exclusively to the cold aisles and pull return air only from the hot aisles.

The hot rack exhaust air is not mixed with cooling supply air and therefore can be directly returned to the air handler, returning air at a higher temperature, often 85°F or higher. The higher return temperature extends economization hours significantly and/or allows for a control algorithm that reduces supply air volume, saving fan power. In addition to energy savings, higher equipment power densities are also better supported by this configuration. The significant increase in economization potential afforded by a hot aisle/cold aisle configuration can improve equipment reliability in mild climates by providing emergency compressor-free data center operation during outdoor air temperatures up to the data center equipment’s top operating temperature (typically 90°F - 95°F). More annual hours of economization also can reduce central plant run-hour related maintenance costs.

Underfloor air supply systems have a few unique concerns. The underfloor plenum serves both as a duct and a wiring chase. Coordination throughout design and into construction is necessary since paths for airflow can be blocked by uncoordinated electrical or data trays and conduit. The location of supply tiles needs to be carefully considered to prevent short circuiting of supply air and checked periodically if users are likely to reconfigure them. Removing tiles to ‘fix’ hot spots can cause problems throughout the system.

Light fixtures and overhead cable trays should be laid out in coordination with the HVAC air supply to ensure no obstructions interrupt the delivery and removal of air to the rows. Hanging fixtures or trays directly under an air supply should be avoided.

Such designs should be evaluated on the basis of their effectiveness in capturing hot exhaust air with a minimum of ambient air mixing (typically achieved by placing the capture opening very close to the hot exhaust) and factoring in any fan energy costs associated with the systems. Exhaust systems typically have far higher fan energy costs than standard returns, so the use of small diameter ducting or hoses and multiple small fans should be carefully evaluated to ensure that additional fan power cost does not seriously reduce or eliminate the savings anticipated from improved air management.

Diffusers that dump air straight down should be selected and located directly in front of racks, not above or behind. Unlike an office space design, diffusers should be selected and placed in order to dump air directly to where it can be drawn in the equipment, rather than to provide a fully mixed room without human-sensible drafts. The thermostat should be located in an area in front of the computer equipment, not on a wall behind the equipment. Finally, where a rooftop unit is being used, it should be located centrally over the served area – the required reduction in ductwork will lower cost and slightly improve efficiency. While maintenance and roof leak concerns may preclude locating the unit directly over data center space, often a relatively central location over an adjacent hall or support area is appropriate.

Principles Air Management

- Use of best-practices air management, such as strict hot aisle/cold aisle configuration, can double the computer server cooling capacity of a data center.

- Combined with an air-side economizer, air management can reduce data center cooling costs by over 60%1.

- Removing hot air immediately as it exits the equipment allows for higher capacity and much higher efficiency than mixing the hot exhaust air with the cooling air being drawn into the equipment. Equipment environmental temperature specifications refer primarily to the air being drawn in to cool the system.

- A higher difference between the return air and supply air temperatures increases the maximum load density possible in the space and can help reduce the size of the cooling equipment required, particularly when lower cost mass produced package air handling units are used.

- Poor airflow management will reduce both the efficiency and capacity of computer room cooling equipment. Examples of common problems that can decrease a Computer Room Air Conditioning (CRAC) unit’s usable capacity by 50%2 or more are: leaking floor tiles/cable openings, poorly placed overhead supplies, underfloor plenum obstructions, and inappropriately oriented rack exhausts.

Fan energy savings are realized by reducing fan speeds to only supply as much air as a given space requires. There are a number of different design strategies that reduce fan speeds, but the most common is a fan speed control loop controlling the cold aisles’ temperature at the most critical locations – the top of racks for underfloor supply systems, the bottom of racks for overhead systems, end of aisles, etc. Note that many computer room air conditioners use the return air temperature to indicate the space temperature, an approach that does not work in a hot aisle/cold aisle configuration where the return air is at a very different temperature than the cold aisle air being supplied to the equipment. Control of the fan speed based on the server inlet temperature is critical to achieving savings. Higher return air temperature also makes better use of the capacity of standard package units, which are designed to condition office loads. This means that a portion of their cooling capacity is configured to serve humidity (latent) loads. Data centers typically have very few occupants and small ventilation air requirements (assuming no air-side economizing in a typical facility), and therefore have negligible latent loads. While the best course of action is to select a unit designed for sensible-cooling loads only or to increase the airflow, an increased return air temperature can convert some of a standard package unit’s latent capacity into usable sensible capacity very economically. This may reduce the size and/or number of units required.

Air Management Hot Aisle/Cold Aisle

A basic hot aisle/cold aisle configuration is created when the equipment racks and the cooling system’s air supply and return are designed to prevent mixing of the hot rack exhaust air and the cool supply air drawn into the racks. As the name implies, the data center equipment is laid out in rows of racks with alternating cold (rack air intake side) and hot (rack air heat exhaust side) aisles between them. The aisles are typically wide enough to allow for maintenance access to the racks and meet any code requirements. All equipment is installed into the racks to achieve a front-to-back airflow pattern that draws conditioned air in from cold aisles, located in front of the equipment, and rejects heat out through the hot aisles behind the racks. Equipment with non-standard exhaust directions must be addressed in some way (shrouds, ducts, etc.) to achieve a front-to-back airflow. The rows of racks are placed back-to-back, and holes through the rack (vacant equipment slots) are blocked off on the intake side to create barriers that reduce recirculation. With proper isolation, the temperature of the hot aisle no longer impacts the temperature of the racks or the reliable operation of the data center; the hot aisle becomes a heat exhaust. The HVAC system is configured to supply cold air exclusively to the cold aisles and pull return air only from the hot aisles.

The hot rack exhaust air is not mixed with cooling supply air and therefore can be directly returned to the air handler, returning air at a higher temperature, often 85°F or higher. The higher return temperature extends economization hours significantly and/or allows for a control algorithm that reduces supply air volume, saving fan power. In addition to energy savings, higher equipment power densities are also better supported by this configuration. The significant increase in economization potential afforded by a hot aisle/cold aisle configuration can improve equipment reliability in mild climates by providing emergency compressor-free data center operation during outdoor air temperatures up to the data center equipment’s top operating temperature (typically 90°F - 95°F). More annual hours of economization also can reduce central plant run-hour related maintenance costs.

Underfloor air supply systems have a few unique concerns. The underfloor plenum serves both as a duct and a wiring chase. Coordination throughout design and into construction is necessary since paths for airflow can be blocked by uncoordinated electrical or data trays and conduit. The location of supply tiles needs to be carefully considered to prevent short circuiting of supply air and checked periodically if users are likely to reconfigure them. Removing tiles to ‘fix’ hot spots can cause problems throughout the system.

Light fixtures and overhead cable trays should be laid out in coordination with the HVAC air supply to ensure no obstructions interrupt the delivery and removal of air to the rows. Hanging fixtures or trays directly under an air supply should be avoided.

Air Management Flexible Barriers

Using flexible clear plastic barriers, such as plastic supermarket refrigeration covers or other physical barriers, to seal the space between the tops of the rack and the ceiling or air return location can greatly improve hot aisle/cold aisle isolation while allowing flexibility in accessing, operating, and maintaining the computer equipment below. One recommended design configuration supplies cool air via an underfloor plenum to the racks; the air then passes through the equipment in the rack and enters a separated, semi-sealed area for return to an overhead plenum. This displacement system does not require that air be accurately directed or overcooled. This approach uses a baffle panel or barrier above the top of the rack and at the ends of the cold aisles to eliminate “short-circuiting” (the mixing of hot and cold air). These changes should reduce fan energy requirements by 20–25 percent, and could result in a 20 percent energy savings on the chiller side.Air Management Ventilated Racks

The ideal air management system would duct cooling air directly to the intake side of the rack and draw hot air from the exhaust side, without diffusing it through the data center room space at all. Specialized rack products that utilize integral rack plenums that closely approximate this ideal operation are beginning to appear on the market. Custom solutions can also be designed using the well defined design principles used for heat and fume exhaust systems.Such designs should be evaluated on the basis of their effectiveness in capturing hot exhaust air with a minimum of ambient air mixing (typically achieved by placing the capture opening very close to the hot exhaust) and factoring in any fan energy costs associated with the systems. Exhaust systems typically have far higher fan energy costs than standard returns, so the use of small diameter ducting or hoses and multiple small fans should be carefully evaluated to ensure that additional fan power cost does not seriously reduce or eliminate the savings anticipated from improved air management.

Optimized Supply/Return Configuration

All of the design methods discussed above are approaches to optimizing the airflow through a data center to minimize the mixing of cool supply air and hot waste heat from the equipment. A comprehensive design approach to air management is the single best approach to improving efficiency; however, in retrofit situations or where no resources are available to properly implement airflow control, some simple, lowcost steps can help a data center operate slightly more efficiently.Diffusers that dump air straight down should be selected and located directly in front of racks, not above or behind. Unlike an office space design, diffusers should be selected and placed in order to dump air directly to where it can be drawn in the equipment, rather than to provide a fully mixed room without human-sensible drafts. The thermostat should be located in an area in front of the computer equipment, not on a wall behind the equipment. Finally, where a rooftop unit is being used, it should be located centrally over the served area – the required reduction in ductwork will lower cost and slightly improve efficiency. While maintenance and roof leak concerns may preclude locating the unit directly over data center space, often a relatively central location over an adjacent hall or support area is appropriate.

- [accordion]

- (1) The 4 Rs of Airflow Management

-

- (2) Design, Supply, Installation, Testing and Commissioning of HPC-BYOH

- (3) Fundamentals of Data Centre

- (4) The 12 Essential Elements Data Center Facility Operations

- (5) Building a Modern Data Center Ebook

- (6) Tips Soq Data Center Commissioning

- (1) The 4 Rs of Airflow Management

- (2) Design, Supply, Installation, Testing and Commissioning of HPC-BYOH

- (3) Fundamentals of Data Centre

- (4) The 12 Essential Elements Data Center Facility Operations

- (5) Building a Modern Data Center Ebook

- (6) Tips Soq Data Center Commissioning

M. Rizka Anugrah

M. Rizka Anugrah Rani Annisa Royani

Rani Annisa Royani